PRODUCT

CONTACT US

Contact Person:Ms.Vera; Ms.Elena

Mob:0086-13961615106;0086-18961680026

Direct line:0086-510-86625061

WhatsApp:0086-13961615106

Wechat:0086-13961615106

E-mail:vera@true-china.com

PSA Oxygen Generator with oxygen booster &filling system oxygen purtiy 93%

Key words:

Nitrogen Generators, Air Compressors, Oxygen and Other Gas Processing Equipment

Category:

Product Description

PSA Oxygen Generator with oxygen booster &filling system oxygen purtiy 93%

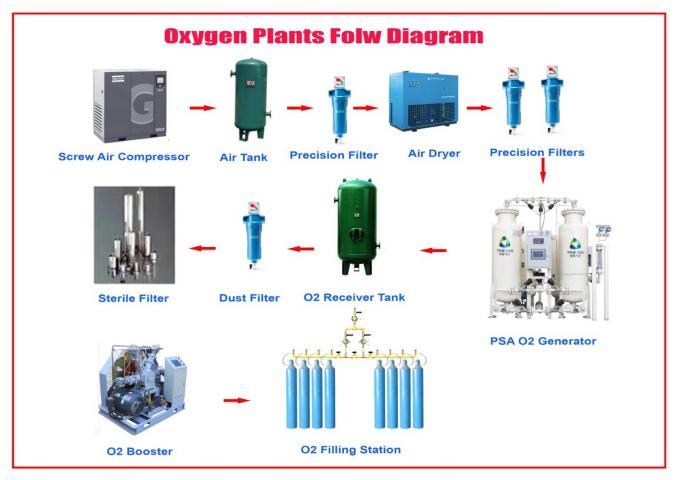

Working Principle

Atmospheric desorption PSA oxygen generator use the clean compressed air as raw material,zeolite molecular sieve as the adsorbing material ,use the pressure swing adsorption principle to get the oxygen under normal temperature.According to the difference adsorbing capacity of oxygen,nitrogen up the zeolite molecular sieve surface,and the difference diffusion rate of oxygen,nitrogen under ZMS,through Programmable Controller control the sequencing valve open/close,complete Pressure adsorption ,Decompression desorption process,complete Separation of oxygen and nitrogen ,get the demanded purity oxygen.

Main characteristic

1. Use the man-machine interface,intelligentize control,operation easy,supply the qualified oxygen in short time.

2. High efficiency fill in ZMS,tighter,solid,longer usage life

3. Use Siemens , OMRON PLC control and Germany BURKERT pneumatic valve to change system automatically,working stable.

4. Pressure,purity,flow can adjustable,to satisfied customers’ requirements.

5. Whole sealing design,Structural tension ,beautiful appearance,save floor area

Technical data Application fields

Purity:90%±3% Widely used in non-ferrous metal Capacity:1-1000Nm3/h metallurgy,chemical industry,

Pressure:0.1-0.5Mpa cement produce,pulp,

Dew point:≤40℃ paper making,glass stoves

Waste water/gas treatment

Application scope

1. Medical.The generator can be set up to fill the hospital pipeline directly and use the filling ramp as a backup system. Oxygen cylinders can be filled simultaneously or during hours with low consumption.

2. Metallurgy: For anneal protection, agglomeration protection, nitrogenizing, furnace washing and blowing, etc. Used in fields such as metal heating treatment, powder metallurgy, magnetic material, copper process, metallic mesh, galvanized wire, semiconductor, etc.

3. Chemical and new material industries: For chemical material gas, pipeline blowing, gas replacement, gas protection, product transport, etc. Used in fields such as chemical, urethane elastic fiber, rubber, plastic, tyre, polyurethane, biological technology, intermediate, etc.

4. Electronic industry: For encapsulation, agglomeration, anneal, deoxidization, storage of electronic products. Used in fields such as peak welding, circumfluence welding, crystal, piezoelectricity, electronic porcelain, electronic copper tape, battery, electronic alloy material, etc.

TYO25-90+/-3% specification and technical details

| Name | Model | Unit | Qty | Manufacturer | Technical parameter |

|

Screw compressor

|

G37-8 | set | 1 | Atlas Copco |

gas production:6.38m³/min Power:37kw pressure:0.85mpa Voltage:380V/3PH/50HZ |

| Air tank | CG-1.0/0.8 | set | 1 | Professional manufacturer |

volume:1.0m3 working pressure:0.8mpa (including certificates and accessories) |

| Refrigerated Air dryer | TY-6HTF | set | 1 | True Gas |

Treatment capacity: 6.8m³/min power:1.5kw pressure:1.0mpa Power Supply:220V/50HZ |

| Filters | C-T-A-H | set | 1 | True Gas |

Rated pressure: 1.0Mpa Rated handling flow:7m3/min Air quality after filtration: particulate≤0.01μm oil≤0.003ppm filter pressure drop:≤0.2bar Filter of all levels of the configuration system shall be configured with timed electronic discharge valve and manual draining valve. |

| Oxygen generating unit | TYO25-90 | set | 1 | True Gas |

Gas production: ≥25Nm3/h Oxygen purity: ≥90%±2% Intake pressure:≥0.6mpa Oxygen outlet pressure:0.4MPa Power Supply:220V/50HZ power:0.5kw The service life of carbon molecular sieve is more than 5-8 years |

| Oxygen buffer tank | CG0.3/0.8 | unit | 1 | Professional manufacturer |

volume:0.3m3 working pressure:0.8mpa (including certificates and accessories)

|

| Oxygen tank | CG1.0/0.8 | unit | 1 | Professional manufacturer |

volume:1.0m3 working pressure:0.8mpa (including certificates and accessories) |

| Oxygen booster | VW-25/4-150 | unit | 1 | Anqingbailian/Anshanjiapeng |

Intake pressure:0.4mpa Discharge pressure:15.0mpa power:10kw Voltage:380V 50HZ |

| Bus bar | TY-25/150 | group | 1 | True-Gas |

Filling Pressure:15.0Mpa Filling port:10 |

Feedback

Related Products